J-PARC Center

November 1, 2007 |

Mercury circulation for spallation neutron source in J-PARC

has been succeeded

- Small induction pump for liquid metal has been developed - |

|

|

Point

The permanent magnet rotating type induction pump (PM pump)3) has been developed and installed in the mercury circulation system2) of neutron spallation source in J-PARC (Japan Proton Accelerator Research Complex)1) and it could supply a great deal of mercury (20 tons) to a mercury target5).

This newly developed PM pump can be small and can provide sufficient mercury flowing by using the strong permanent magnet to apply the induction force into mercury. The PM pump is expected to use for general industrial field as a pump for molten metals (ex. Pump for molten aluminum alloy forging to make automobile engine.)

Summary

J-PARC center which is managed by JAEA and KEK are proceeding to construct and operate J-PARC facilities. 6 times intense neutron beam will be produced by spallation neutron source facility in J-PARC and the neutron beam4) will be used for experiments in various fields. R & D on the neutron source with a high power target is being carried out in JAEA.

The neutrons are produced by the spallation reaction6) in the spallation neutron source due to bombarding accelerated proton beam to a mercury target with a heat generation in the target. In conventional spallation neutron sources, the system in which heavy metal solid-target was cooled by water was adopted. However it is difficult to cool the solid target by water in the high power target aimed in J-PARC. Therefore, the liquid metal target system using the mercury l was adopted because mercury had both functions of neutron spallation source and cooling material.

In the mercury target system, mercury must be circulated by a mercury circulation system. A mechanical pump could be small however it was worried about mercury leak from the seal around the drive shaft of the pump. On other hand, an induction pump has no seal but efficiency was worse so that it was difficult to achieve the enough mercury flow to cool the target.

Then, JAEA developed the PM pump in corporate with Sukegawa denki Co. This newly developed PM pump can be small and can provide sufficient mercury flowing by using the strong permanent magnet to apply the induction force into mercury.

|

|

[Term]

- 1) Japan Proton Accelerator Research Complex (J-PARC)

- J-PARC is generic name of the Proton Accelerators and Experimental facilities which are being constructed in Tokai-mura, Japan by cooperation between Japan Atomic Energy Research Agency (JAEA) and KEK.

In J-PARC, innovative research and industrial application research experiments will be carried on by using the particles such as neutrons, muons and neutrinos which are produced by collision of the accelerated protons into target materials.

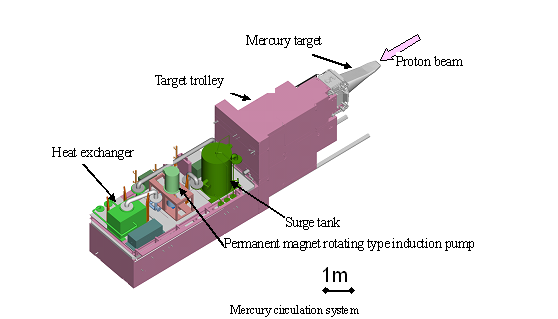

- 2) Mercury circulation system (*Footnote1)

- Mercury circulation system provides mercury for mercury target and circulates mercury in the mercury target and the system. The system is set on the back of the mercury target toward proton beam going direction. Main components of the system are pump, heat exchanger and surge tank. These components are connected by pipes of 150 mm in diameter to circulate the radioactive mercury without leak.

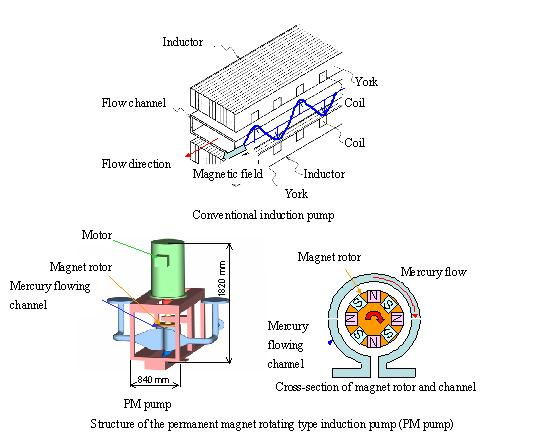

- 3) Permanent magnet rotating type induction pump (PM pump) (*Footnote2)

- In the PM pump, mercury flowing channel is set around the magnet rotor which is cylindrical shape. The N and S poles of permanent magnets are alternatively arranged on the surface of the magnet rotor. Mercury is drove by the Lorenz force generated by rotation of the magnet rotor.

- 4) Neutron beam

- Neutrons and secondary particles radiate due to the spallation reaction by the accelerated protons incident in the spallation target. The neutrons moderated in the optimized energy and extracted in the uniform direction are called neutron beam. This neutron beam will be used for the neutron scattering experiments etc. The intensity of neutron beam in J-PARC is more than 6 times higher than that in ISIS (UK, Proton beam power: 160 kW) which has been the most powerful spallation neutron source in the world yet.

- 5) Target

- The secondary particles such as neutrons are produced by the spallation reaction when the accelerated protons incident high atomic number materials such as heavy metal. The high atomic number material called target material. The system consists of the target material and vessel to contain the target material and the coolant to remove heat generate in the spallation reaction is called target. In the conventional target system, solid heavy metals such as tungsten or tantalum have been used with water coolant. However it is difficult to keep both of high neutron yield and solid target cooling when the proton beam power becomes high.

- 6) Spallation reaction

- When high-energy protons incident atoms, the atoms break up to yield secondary particles such as neutrons and to generate heat. This reaction is called spallation reaction.

|

|

[Footnote 1]

In neutron spallation source, the proton beam bombards the heavy metal to produce neutron beam. Mercury is used as the target material in J-PARC, the mercury circulation system is set on the back of the mercury target toward proton beam going direction to circulate mercury into the mercury target. Main components of the system are PM pump, heat exchanger and surge tank. These components are connected by pipes of 150 mm in diameter to circulate the radioactive mercury. Mercury of 1.2 m3 in total volume is circulated with 41 m3/h in flow rate to and heat generated in the mercury target of about 500 kW is removed by the heat exchanger.

Since mercury is radioactivated by spallation reaction, the components must be exchanged by remote handling. The components is set on the narrow space of 5.4 m in length and 2.6 mm in width on a target trolley which can be moved from an operation position to produce neutrons to maintenance position where the components is exchanged.

|

|

[Footnote 2]

A conventional induction pump drive the fluid due to the Lorentze force generated by the moving magnetic fields perpendicular to the fluid flowing direction which is produced by current in coils set around flowing channel. Since the driving force for fluid flowing is proportional to the length applying the magnetic field, the length becomes long to get large driving force.

In the PM pump, mercury flowing channel is set around the magnet rotor which is cylindrical shape. The N and S poles of permanent magnets are alternatively arranged on the surface of the magnet rotor. Mercury is drove by the Lorentze force generated by rotation of the magnet rotor. Then, JAEA developed the PM pump in corporate with Sukegawa denki Co. This newly developed PM pump can be small and can provide sufficient mercury flowing by using the strong permanent magnet to apply the induction force into mercury. On the other hand, because loss of the Lorentze force generate heat in induction pump, motor of 90 kW is set in to rotate the magnet rotor of PM pump from the viewpoint of capacity of heat exchanger. And the configuration of flowing channel duct is optimized to satisfy the conflicting characteristics; structural integrity and reduction of the heat generation. Consequently, PM pump can drive mercury continuously with sufficient flow rate to remove the heat generated by the spallation reaction. Additionally, the PM pump can be operated with low noise and low vibration.

|

|

Copyright 2007 JAEA and KEK Joint Project. All rights reserved. |