Seeking High-quality, High-intensity Beams

- Development of Beam Profile Monitor Based on Carbon Nanotubes -

Carbon nanotubes, which are receiving attention as a material that is highly conductive and thin but strong, are also used in the accelerator of J-PARC. They are used in the beam profile monitor, which measures how the particle distribution of the beam that runs inside the accelerator, and helped supplying high-quality beams. We interviewed Mr. Miyao of Accelerator Section VII, Accelerator Division, J-PARC center, who is responsible for the engineering of this monitor (interviewed by the Public Relations section of J-PARC).

What Is Important about the Role of the Beam Profile Monitor?

High intensity, which characterizes the accelerator of J-PARC, means that each beam contains many particles. However, such particles can cause an unwanted situation. For example, if these particles diffuse while travelling inside the beam pipe of the accelerator, they hit the wall of the pipe, generating unwanted particles. The beam profile (shape) monitor measures particle distributions of the beam so as to produce high-quality beams that do not allow for such unwanted situations. "Today, I will talk about a monitor that allows you to check the beam shape after the beam has exited the radio-frequency quadrupole linac (RFQ)-the first stage of the four-stage acceleration mode of the linac system-and before it enters the drift-tube linac (DTL)." Mr. Miyao explains so while showing a diagrammatic illustration of the linac system.

Diagrammatic Illustration of the Linac System

How is the Beam Profile Measured?

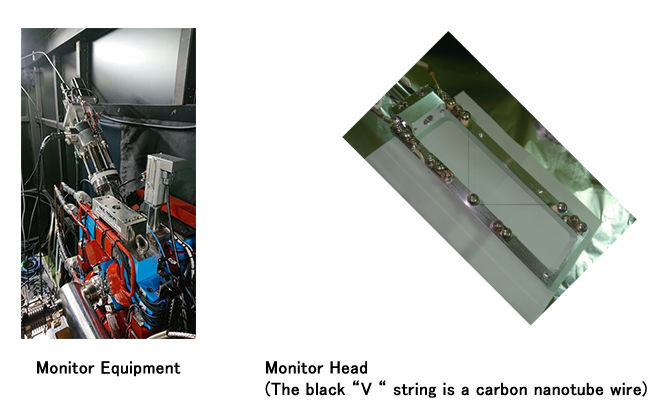

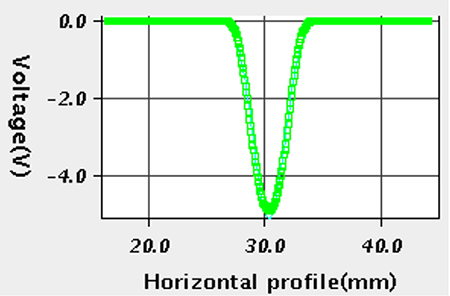

The monitor is structured as shown the left photo below: inside a frame, carbon nanotube wires are horizontally and vertically stretched, and when negative hydrogen ions (*) hit the wires, electrons are stripped from the ions and flow inside the wires. The monitor transforms the current to a voltage to detect negative hydrogen ions. By detecting negative hydrogen ions while moving the head in an oblique direction across the beam, it finds out how the ions are distributed inside the beam. Mr. Miyao showed us a sample of a measured beam profile (shown below) on the screen of a PC, and commented "this example shows a good condition where the current density of the negative hydrogen ions is high and the horizontal spread is restrained to approximately 3.0 mm."

(*) Negative hydrogen ion: While the accelerator of J-PARC is a proton accelerator, the linac system accelerates negative hydrogen ions that have two electrons attached to the proton and removes the two electrons in the following RCS to transform them into protons.

<Monitor Structure>

<A sample of a measured beam profile>

Why Are Carbon Nanotubes Used?

"Traditionally, carbon fibers (with a diameter of 7µm) were used. Carbon materials are said to be relatively less likely to break, even if they are exposed to beams because of their low energy loss. The traditional carbon fibers, however, are likely to break if exposed to beams because of their low tensile strength. It takes time to replace broken fibers because they are thin, which makes it difficult to use them under an operation situation where maintenance time is decreasing. This is a critical issue that affects the quality of the beams to be supplied." Mr. Miyao says to explain the difficulty he faced in the past.

In his graduate school days, Mr. Miyao specialized in physical properties of various materials, including carbon nanotubes. When breakage of fibers used in monitors was plaguing him, he came across a carbon-nanotube product in an enterprise exhibition booth attached to the building of the Particle Accelerator Society of Japan, which claimed to bear even a weight of 100 g hung on the product without breaking. He says, "he thought a beam profile monitor could be used more easily." "The fact that the product does not break even if it is pulled does not necessarily mean that it does not break when it is exposed to a beam. But I thought this would make way. At once, I begged my boss and was allowed to buy that product in 2017. Then, I made a monitor using this product and conducted experiments on it." The passion of Mr. Miyao, who had been seeking to supply high-quality beams, finally bore fruit. The developed monitor has proved to sufficiently endure pre-operation beam adjustment in the present 500-kW commercial operation.

To Contribute to the High-intensity Beam of J-PARC

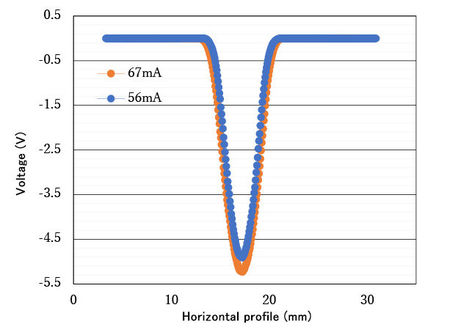

J-PARC aims for an output of 1 MW. Mr. Miyao is conducting performance experiments on the beam profile monitor to support high-intensity beams of 1 MW and even higher intensities. "Recently, I have verified that even the beam intensity corresponding to 1 MW (beam energy of 3 MeV and beam currents of 56 mA and 67 mA) can be safely used to measure beam profiles without problems as shown in the figure below. If the traditional carbon fibers are exposed to such high-intensity beams, the beam shapes cannot be accurately measured due to the effect of thermal electrons (which are emitted when heated). A higher beam intensity makes wires easier to break; through the experiments, the measurements after the wires had been exposed to beams have revealed that they had not been damaged much." Mr. Miyao announced this result in a poster session at the J-PARC 10th anniversary symposium held on September 24 through 26, 2019. Mr. Miyao will continue to work toward supporting higher intensities.

Distribution of negative hydrogen ions in a high-intensity beam corresponding to 1 MW, measured with a beam profile monitor based on carbon nanotubes. This chart indicates that the density of the negative hydrogen ions is highest at the point of 18 mm and that ions are normally distributed within a horizontal width of approximately 3.6 mm.

【Publication】

Poster presentation "Beam profile measurement with carbon nanotube wire at J-PARC Linac," at J-PARC 10th anniversary commemorative symposium.

Tomoaki Miyao

Associate Engineer, J-PARC Center Accelerator Division Accelerator Section VII,

High Energy Accelerator Research Organization

Tomoaki Miyao comes from Kanagawa Prefecture. As a master's student, he conducted experiments to study the physical properties of carbon nanotubes at Photon Factory in the Tsukuba Campus, KEK. At present, as a member of the linac monitor group, he is responsible for maintaining and managing the beam diagnostics team. His interests are watching baseball games and travelling. Recently, he supports Shishamoneko, the mascot character of Tokushima Prefecture. In his private life, he is actively involved in softball tournaments held in the J-PARC center and watches professional baseball games with enthusiasm. Note that he wears a work uniform in the motion video.