Why Does Titanium Alloy Beam Window Become Brittle After Proton Beam Exposure ?

- Research and Development on the Accelerator Target and Beam Window Materials by RaDIATE International Collaboration -

RaDIATE International Collaboration

J-PARC Center

High Energy Accelerator Research Organization (KEK)

Japan Atomic Energy Agency (JAEA)

Fermi National Accelerator Laboratory (FNAL)

Pacific Northwest National Laboratory (PNNL)

Brookhaven National Laboratory (BNL)

Science and Technology Facilities Council (STFC) Rutherford Appleton Laboratory (RAL)

Highlights of the Achievement

✣ A high-strength titanium alloy Ti-6Al-4V is widely employed as the "beam window" at high-intensity proton accelerator facilities, such as FNAL and J-PARC. However, this alloy suffers from radiation-induced hardening and loss of ductility after proton beam exposure. It is urgent to clarify the source of this degradation in mechanical properties to achieve stable high-intensity beam operations at these facilities, aiming to validate leptonic CP-violation by conducting long-baseline neutrino oscillation experiments.

✣ An international collaboration conducted high-intensity proton beam exposure on various accelerator target and beam window materials, followed by post-irradiation examinations with state-of-the-art analytical equipment. As a result, it has been clarified that in Ti-6Al-4V, a high density of nanoscale defect clusters in the primary alpha Ti phase lead to extreme hardening and loss of ductility, further exacerbated by the evolution of a high density of small "omega phase" particles in the beta phase. These observations suggest that defects in the alpha phase are most likely responsible for the observed radiation hardening, as demonstrated in other metallic systems after moderately low irradiation temperature proton or neutron irradiation. The formation and growth of radiation-induced high-density omega phase precipitates, first observed in this study in proton-irradiated Ti-base alloys, is worthy of further investigation to clarify their role in mechanical property degradation.

✣ Understanding the sources of radiation hardening in Ti-6Al-4V and other alloys will guide the final choice of alloy grade and proper heat-treatment method to allow for the next-generation beam window to withstand the high-intensity proton beam operation. It may also be beneficial for the development of new radiation damage-tolerant materials for fusion reactors and accelerator-driven nuclear transmutation systems.

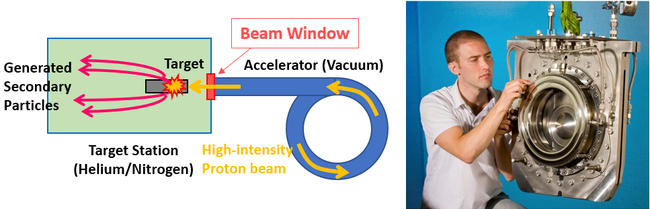

Figure 1:(Left) The "beam window" is a thin wall separating the accelerator from the target station. High intensity proton beams, accelerated towards the target, are repeatedly injected through the beam window. (Right) The beam window at the J-PARC neutrino experimental facility, fabricated from high-strength titanium alloy Ti-6Al-4V (Copyright: STFC RAL).

Background

The large-scale proton accelerator facilities around the world, such as Fermi National Accelerator Laboratory (FNAL) at Illinois, U.S.A. and Japan Proton Accelerator Research Complex (J-PARC) at Tokai-village, Ibaraki-prefecture, Japan, accelerate proton beams and collide them with target materials (referred to as "irradiation"). The collisions produce particles, such as neutrinos, hadrons, neutrons, and muons, which are subsequently used for research into elementary particle and nuclear physics, material and life sciences, and for the development of fusion reactors and accelerator-driven nuclear transmutation systems. The accelerator operates under vacuum to lower the probability of scattering the accelerated protons by air molecules. The target is situated inside of a helium-filled or nitrogen-filled chamber referred to as the target station that must be separated from the accelerator chamber by a thin metal membrane referred to as the "beam window" (Fig.1). The beam window is repeatedly exposed to a high-intensity proton beam accelerated towards the target, subjecting the metal window to instantaneous thermal shocks that create pressure waves.

For the beam window, thin, lightweight materials are chosen to minimize the deposited energy and subsequent heating, and high strength is desired to withstand the repeated thermal shocks. However, when beam windows and target materials are exposed to the proton beam, atomic displacements (referred to as "radiation damage") occur that knock atoms and clusters of atoms from their atomic lattice sites in metals. Radiation damage is a serious problem that degrades the mechanical properties of the material, and depending on the temperature, can cause dimensional changes due to void swelling and accumulation of defects.

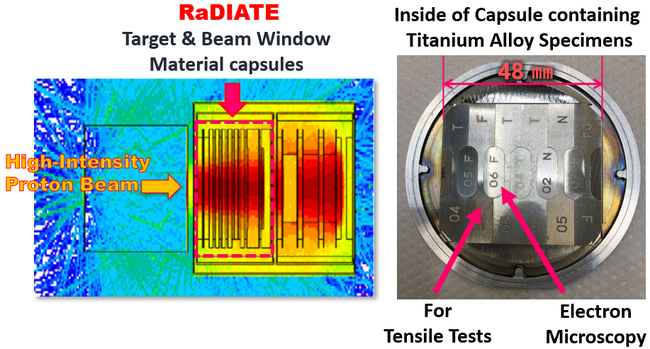

For the validation of the leptonic charge-parity (CP) violation (*1), both FNAL and J-PARC are planning to increase their beam intensities to Mega-Watt class, which is much higher than the current power. To enable this push to the frontier of high energy physics, it is important to predict and even increase the lifetime of targets and beam windows by developing or choosing radiation damage tolerant materials. To address this problem, several leading accelerator laboratories and reactor/fusion research facilities in the U.S.A., Europe, and Japan are cooperating under the RaDIATE international collaboration (*2). From 2017 to 2018, the RaDIATE collaboration performed a proton irradiation experiment in the Brookhaven Linac Isotope Producer (BLIP) at Brookhaven National Laboratory (BNL), the aim of which was to expose various candidate materials for beam windows and targets to a high-intensity proton beam. Titanium alloys were included in the irradiated materials of the experiment, motivated by the current and future use of the titanium alloys for the beam windows at the J-PARC neutrino experimental facility and the potential use of Ti alloys for beam windows for neutrino beam facilities at Fermilab (Long-Baseline Neutrino Facility). There are concerns that the beam windows may not withstand the continual thermal shocks at the expected much higher beam powers because of radiation-induced changes in mechanical properties. After irradiation, material specimens were then transported to Pacific Northwest National Laboratory (PNNL) for detailed examinations by the state-of-the-art analytical equipment. Figure 2 shows some of the titanium alloy material specimens assembled inside a container, referred to as an irradiation capsule, prior to capsule sealing and irradiation.

Research Methods and Achievements

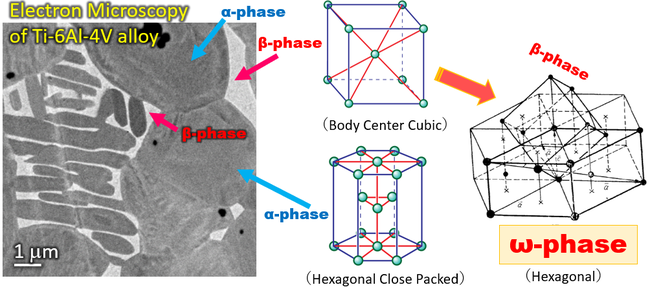

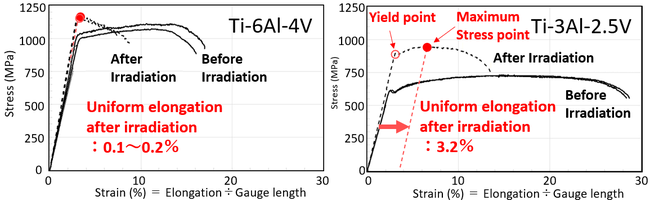

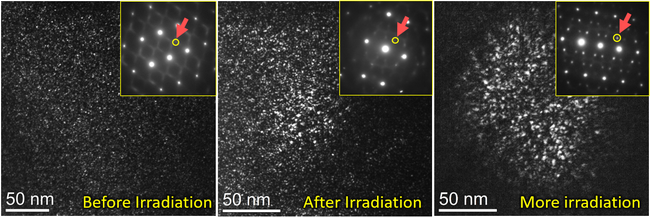

Up to now, the J-PARC neutrino experimental facility employs titanium alloy Ti-6Al-4V, i.e., titanium (Ti) with the addition of 6% aluminum (Al) and 4% vanadium (V), for its beam window, which has a high strength among lightweight titanium alloys. When pure Ti is heated to 885℃, the titanium undergoes a phase transformation from the lower temperature α-phase to the higher temperature β-phase. The Al and V are intentionally added because they stabilize the α-phase and β-phase, respectively, producing an alloy that can be heat treated to produce a dual-phase structure that can be tailored to yield desired mechanical properties (Fig. 3). However, after irradiation, tensile tests on the Ti-6Al-4V specimens irradiated to relatively low doses exhibited almost complete loss of uniform elongation and the associated increase in the yield point (termed embrittlement), which may impact the performance of the beam window (*3). On the other hand, the Ti-3Al-2.5V alloy, another dual α+β phase alloy but with less β-phase, retained uniform elongation of three percent, even after three times more irradiation (Fig. 4). To begin to understand the cause of this remarkable difference of tensile behavior between these two alloys, the irradiated Ti-6Al-4V has been investigated using a state-of-the-art transmission electron microscope capable of atomic resolution and various analytical modes to probe chemical and structural changes at the nanoscale and above. As a result, a high density of defect clusters forming small dislocation loops was found in the α-phase, and an even higher density of very fine precipitates, referred to as "ω-phase", evolved during irradiation in the β-phase (Fig. 5). A precursor to the ω-phase was present in the alloy before irradiation, but irradiation accelerated the precipitation of this phase, which is known to significantly reduce the ductility of the alloy. All these facts suggest that the significant loss of uniform elongation in the Ti-6Al-4V alloy after irradiation is due to the high density of small defect clusters in the α-phase, further exacerbated by the evolution of the ω-phase in the intergranular β-phase. Further work is needed to completely understand the differences between the two alloys.

Figure 2:(Left) The high-intensity proton beam exposure at the BLIP facility. At the upstream of the capsules for medical isotope production, six capsules containing target and beam window materials, designed and fabricated by RaDIATE Collaboration participants, were installed and high-intensity proton beam exposure was performed. The color represents heat deposition caused by the proton beam (red indicates the hottest temperatures and blue the coolest). (Right) Inside of the Capsule containing titanium alloy specimens for tensile tests and for observations by electron microscopy at the most downstream (6th) location.

Figure 3:Electron microscopy of Ti-6Al-4V alloy. α-phase and β-phase with different crystal structures co-exist. The ω-phase is a very fine precipitate within the β-phase, with a specific relationship to the β-phase orientation.

Significance of the Achievement and Expectation for Future Studies

So far, the titanium alloy Ti-6Al-4V has been utilized as the beam window at the high-intensity proton accelerator facilities. However, it has now been shown that the alloy loses uniform elongation after exposure to relatively low proton doses. It may not be applicable as a beam window for the next-generation of neutrino experimental facilities at FNAL and J-PARC at much higher beam power. Exploration of other alloys and different thermomechanical processing was pursued to identify an acceptable candidate material that can handle the high beam power. Through this research, insight has been gained into how the different titanium alloy grades respond to irradiation. In fact, according to research by the RaDIATE Collaboration, one alloy in particular exhibited much less degradation of material properties after irradiation. This research achieved a major milestone towards the development of a suitable beam window material to handle the higher power beam operations. This research also can be beneficial to the development of radiation-resistant Ti alloys, which may play a role in fusion reactors and accelerator-driven nuclear transmutation systems.

The RaDIATE international collaboration engages in collaborative research to find solutions for the target and beam window materials, which impact all of the premier extensive accelerator facilities in the world. The collaborative approach of international research activities are imperative to help realize the selection of suitable materials for unprecedented high-intensity accelerator operation, which will help drive the breakthroughs in particle and nuclear physics, material and life sciences, and accelerator-driven nuclear transformation technologies.

Figure 4: Stress-strain curves (please refer to the glossary *4) for Ti-6Al-4V (left) and Ti-3Al-2.5V (right). Solid lines are before irradiation and dashed lines are after irradiation. It is clearly observed that Ti-6Al-4V alloy (left) loses almost all uniform elongation after irradiation, i.e., stress decreases immediately after yielding.

Figure 5:Transmission electron micrographs highlight the β-phase in the Ti-6Al-4V alloy. In the electron beam diffraction pattern shown in the inset of left image, distinct streaks appear. These streaks coalesce into discreet diffraction spots (from left to right insets) with increasing proton beam exposure. By selecting one of these streaks/spots as indicated by the red arrows, the ω-phase can be resolved as a high density of bright particles as shown in the main images, that clearly coarsen in size with proton irradiation.

Article Information

| Title | Tensile behavior of dual-phase titanium alloys under high-intensity proton beam exposure: radiation-induced omega phase transformation in Ti-6Al-4V |

|---|---|

| Authors | Taku Ishida1,2, Eiichi Wakai1,3, Shunsuke Makimura1,2, Andrew M. Casella4, Danny J. Edwards4, Ramprashad Prabhakaran4, David J. Senor4, Kavin Ammigan5, Sujit Bidhar5, Patrick G. Hurh5, Frederique Pellemoine5, Christopher J. Densham6, Michael D. Fitton6, Joe M. Bennett6, Dohyun Kim7, Nikolaos Simos7, Masayuki Hagiwara1,2, Naritoshi Kawamura1,2, Shin-ichiro Meigo1,3, Katsuya Yonehara5, On behalf of the RaDIATE COLLABORATION |

| Affiliation | 1 J-PARC Center, 2 KEK, 3JAEA, 4 PNNL, 5 FNAL, 6 STFC RAL, 7 BNL |

| Journal Name | Journal of Nuclear Materials |

| DOI | https://doi.org/10.1016/j.jnucmat.2020.152413 |

Media Contacts for Further Inquiries

*Please replace "[at]" with "@"

Glossary

*1 Leptonic CP violation

The reason for the overwhelming existence of matter relative to anti-matter in our universe is a fundamental mystery. Modern cosmology posits that this condition originated from the "violation" of a fundamental law of physics. The laws of physics are basically symmetric, and the laws applicable to matter particles are also valid for anti-matter particles. Meanwhile, it is known that there is a tiny amount of violation in the symmetry between quarks (elementary particles that constitute matter) and anti-quarks. This symmetry breaking, referred to as "Charge-conjugation (C)- Parity (P) symmetry violation", has not been observed yet on the other fundamental particle group called "leptons", which consists of electrons, muons, and neutrinos. Recently, the T2K international collaboration made an announcement that they obtained an indication of a fairly large CP violation between neutrinos and anti-neutrinos, which were generated at J-PARC, and detected at an underground neutrino observatory 295 km away called "Super-Kamiokande" (check reference). To confirm this indication, a project is underway in Japan to increase the beam power at J-PARC and to construct the "Hyper-Kamiokande" detector with 8 times larger fiducial volume than Super-Kamiokande. In the U.S.A., a project is underway to direct neutrinos from the Long-Baseline Neutrino Facility (LBNF), under construction at FNAL in Illinois, to a detector 1,300 km away at the Deep Underground Neutrino Experiment (DUNE) in South Dakota. To perform these experiments, scheduled to start around 2027, it is necessary to increase the beam power of the proton accelerators that produce neutrinos to Mega-Watt class. Thus, developing materials for targets and beam windows that can tolerate radiation damage from the unprecedented high beam power is crucial.

(reference):J-PARC press release (2020.04.16)

T2K Results Restrict Possible Values of Neutrino CP Phase - Published in Nature, the results are a major step forward in the study of difference between matter and antimatter -

https://j-parc.jp/c/en/press-release/2020/04/16000517.html

*2 RaDIATE International Collaboration

RaDIATE is an abbreviation of "Radiation Damage In Accelerator Target Environments". In 2012, FNAL and STFC advocated the necessity to promote research and development for materials under accelerator target environments, i.e., materials employed for targets, beam windows, collimators, and beam dumps, which suffer direct impingement of high-intensity proton beams, and initiated an international collaboration with FNAL as the lead organization. As of 2020, the collaboration has grown to more than 70 members at 13 institutions in the U.S.A., Europe and Japan, including high-intensity proton accelerator facilities for particle and nuclear physics, spallation neutron sources, and nuclear transmutation research (FNAL, STFC, ORNL, ESS, CERN, J-PARC=KEK&JAEA, etc) and of nuclear research facilities that have rich expertise and technologies to study radiation damage effects on fission and fusion reactor materials (PNNL, Oxford University, JAEA, etc). The collaboration promotes research at the forefront of radiation damage tolerance and thermal shock resistance of materials in challenging irradiation environments.

(reference) RaDIATE International Collaboration Website :

https://radiate.fnal.gov/

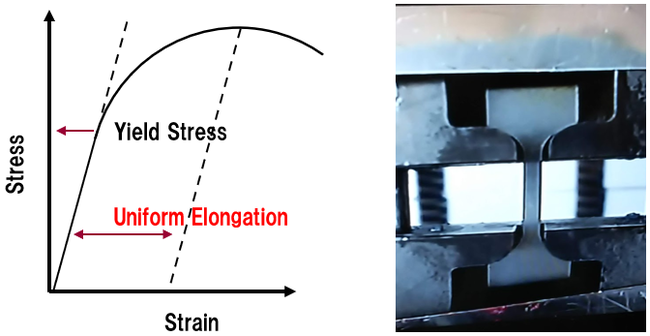

*3 Tensile tests and uniform elongation

When tensile tests are performed, the material initially deforms in proportion to the applied stress. When the stress increases beyond the yield stress, the specimen starts to elongate, and the stress-strain curve departs from linearity. If stress continues to increase, the material elongates uniformly, and the elongation up to the maximum-stress point is referred to as "uniform elongation" (Fig.6). It is important to retain uniform elongation in a structural material because it allows graceful failure without the rapid growth of cracks. Materials are typically hardened after irradiation due to the accumulation of radiation defects, which increases the yield stress of the material. At the same time, uniform elongation is reduced.

This behavior is referred to as radiation hardening and embrittlement.

Figure 6:(Left) Ideal stress-strain curve obtained with tensile testing. (Right) Tensile test at Pacific Northwest National Laboratory (PNNL). By tensioning a dogbone-shaped specimen, the relationship between elongation relative to the original length (strain) and load per unit cross section (stress) is obtained, which provides mechanical properties required for vacuum window design.